Product Details

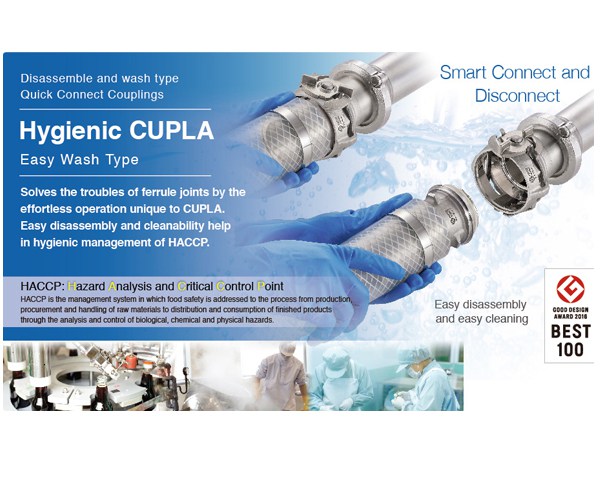

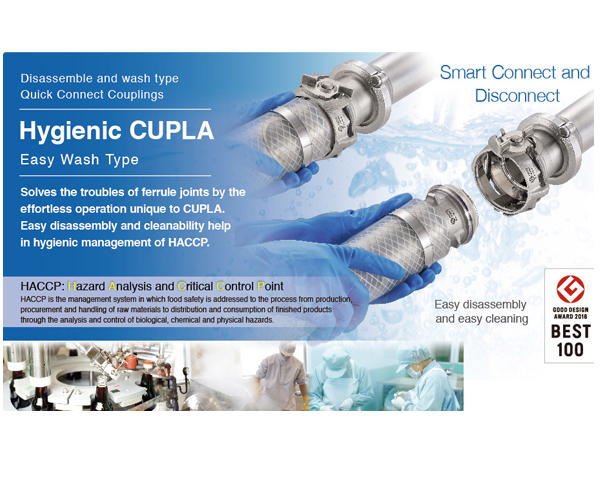

Product Name:Hygienic Cupla

Description

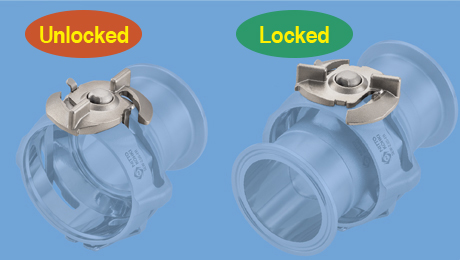

• It can be connected by just inserting the plug to the socket and twisting the "Safety lock".

• The "Safety lock" feature ensures that there can be no unintentional disconnection of the coupling.

• O-rings that conforms to the Food sanitation Act of Japan is adopted.

• An operator friendly design. Seal parts will not drop off during connection like conventional fittings.

• Stainless steel (JIS SUS316L equivalent) for the liquid contact parts, and finished with buffing (#400).

Features

Speedy connection / disconection

Just connect the plug to the socket and twist the "Safety Lock" for connection.

Connection by one person is possible.

Disconnection of plug and socket can be done with ease.

Can be disconnected by unlocking the "Safety Lock" and turning the cam handle. No special skills required.

Corrosion resistant

Stainless steel (JIS SUS316L equivalent) for the liquid contact parts, buffing (#400) to prevent propagation of various bacteria (electro-plating available on request). Less deterioration due to excellent corrosion-proof material.

Versatile

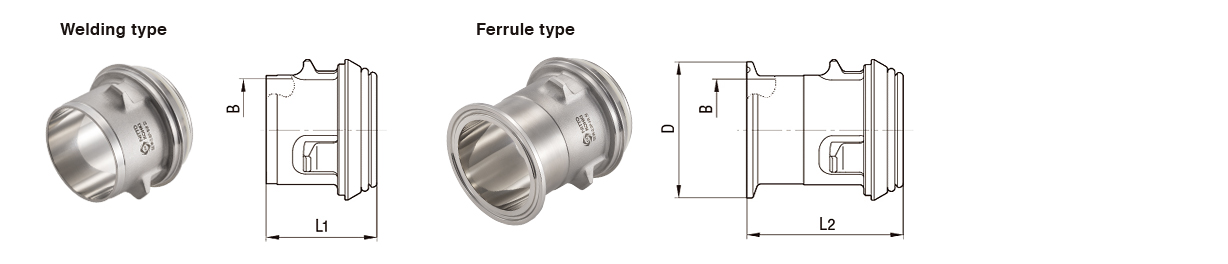

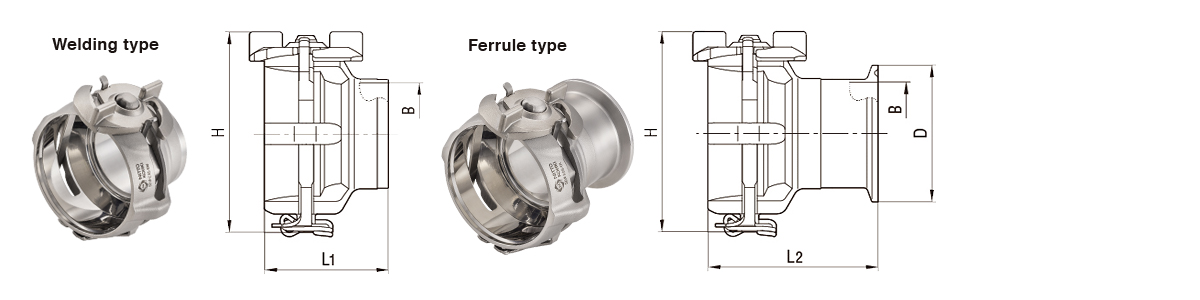

There are two types of end configurations. Ferrule shape (ISO 2852 standard) and welding shape (JIS G 3447 standard).

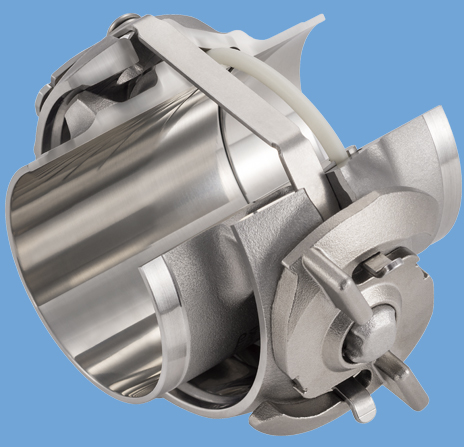

Easy assembly and disassembly / Easy washing of the whole unit

No tools are required to disassemble/assemble Hygienic CUPLA.

Small number of parts that are easy to handle, aiding efficient maintenance.

After disassembly, small number of components requires minimum effort when cleaning. No small parts to lose.

Easy assembly (No special tools required)

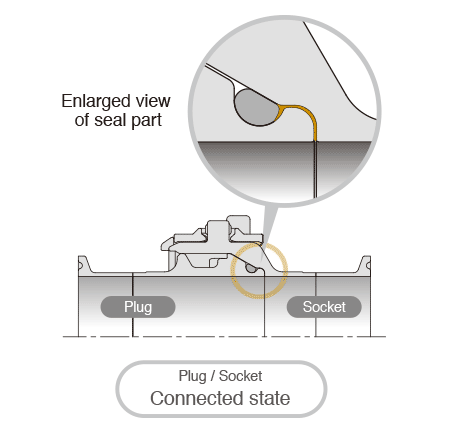

O-ring will not drop off during connection

Since the O-ring is attached beforehand, it will not drop off during connection like conventional fittings.

Safety Lock function

As a safety measure, the "Safety lock" feature ensures that there can be no unintentional disconnection of the CUPLA. By turning the cam handle, you can maintain the connected state of the socket and plug.

Safety Lock

Construction and Safety standards

Since the O-ring is attached beforehand, it will not drop off during connection. And the seal material conforms to article No. 3-D-3-(1) Rubber utensils (except nursing utensils) or Containers/Packages. It has passed both material and elution tests specified in the Food sanitation Act and the standards for Food and Food additives (Notice No.370 of 1959 issued by the Ministry of Health and Welfare of Japan). Also conforms to standard No. 21 CFR 177.2600 of the US Food and Drug Administration (FDA).

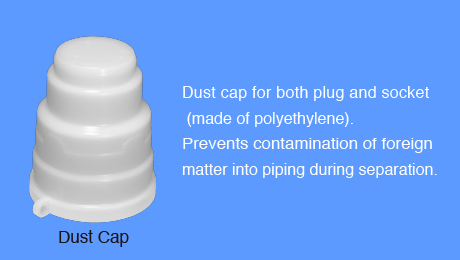

Dust Cap

The Dust Cap conforms to No. 3-D-2-(1) and 3-D-2-(2)-4 Apparatus and Containers/Packages.

It has passed both material and elution tests specified in the standards for Food and Food additives.

(Notice No.201 of revised March 31, 2006 by the Ministry of Health and Welfare of Japan)

Specifications

| Body material |

Stainless steel [ SCS16 (JIS SUS316L equivalent) ] *1

|

|||

| Surface finish of the liquid-contact part |

Buff finish #400

|

|||

| Size of end configurations |

Welding type *2

|

Ferrule type *3

|

||

|

1.5S / 2.0 S

|

||||

| Max. working pressure *4 |

1.0 MPa, 10 kgf/cm², 10 bar, 145 PSI

|

|||

| Seal material Working temperature range |

Seal material *5

|

Mark

|

Working temperature range *6

|

Remarks

|

|

Silicone rubber

|

SI

|

0˚C to +110˚C

|

Standard material

|

|

|

Fluoro rubber

|

FKM

|

0˚C to +180˚C

|

Available on request

|

|

|

Ethylene propylene rubber

|

EPDM

|

0˚C to +150˚C

|

Available on request

|

|

| O-ring size |

1.5 S: P38, 2.0 S: P50 (Dimensions, tolerance: refer to JIS B 2401, Hardness: A70±5)

|

|||

| Suitability for vacuum *7 (Vacuum pressure:53kPa A) |

Socket only

|

Plug only

|

When connected

|

|

|

ー

|

ー

|

Operational

|

||

| Note 1:All metal parts are equivalent to SUS304 except those exposed to liquid contact. Note 2:The dimensions of the weld zone conform to JIS G 3447 stainless steel sanitary pipe. Note 3:Please use ferrule couplings conforming to IDF / ISO 2852. Note 4:The normal allowable fluid pressure under continuous use. May cause leakage or damage if repeatedly used exceeding this pressure. Note 5:The seal material conforms to article No.3-D-3-(1) Rubber utensils (except nursing utensils) or Containers / Packages. It has passed both material and elution tests specified in the Food sanitation Act and the standards for Food and Food additives (Notice No.370 of 1959 issued by the Ministry of Health and Welfare of Japan). Conforms to standard No.21CFR 177.2600 of the US Food and Drug Administration (FDA) . Note 6:Working temperature range that the CUPLA can be used differs depending on the operating conditions. Note 7:Vacuum performance may vary depending upon working environment and usage conditions. |

||||

Models and Dimensions

SEW-1.5P Type / SEW-2.0P Type

| Model | Application | Mass (g) |

Dimensions (mm) | |||

| L1 | L2 | φD | φB | |||

| SEW-1.5P-FR *1 | Welding type | 179 | 52 | - | - | 35.7 |

| SEW-1.5P-BW *1 | Ferrule type |

224

|

- | (73.5) | 50.5 | 35.7 |

| SEW-2.0P-BW *1 | Welding type |

231

|

52 | - | - | 47.8 |

| SEW-2.0P-BW *1 | Ferrule type |

301

|

- | (73.5) | 64 | 47.8 |

|

Note1:A type without seal material is also available. In such case, the model name ends with "-NP".

(ex: SEW-2.0P-BW -NP ) |

||||||

SEW-1.5S Type / SEW-2.0S Type

| Model | Application | Mass (g) |

Dimensions (mm) | ||||

| L1 | L2 | φD | H | φB | |||

| SEW-1.5S-BW | Welding type | 364 | 58 | - | - | (84) | 35.7 |

| SEW-1.5S-FR | Ferrule type | 407 | - | (79.5) | 50.5 | (84) | 35.7 |

| SEW-2.0S-BW | Welding type | 455 | 58 | - | - | (94) | 47.8 |

| SEW-2.0S-FR | Ferrule type | 526 | - | (79.5) | 64 | (94) | 47.8 |

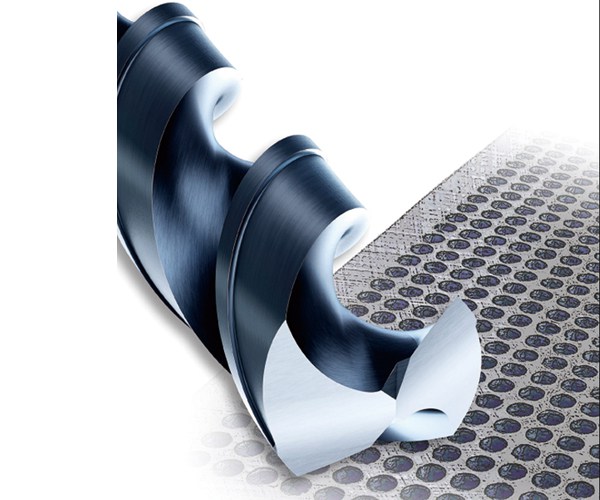

Seal part (cross section)

Because of the structure of this product, dead space is generated when using.

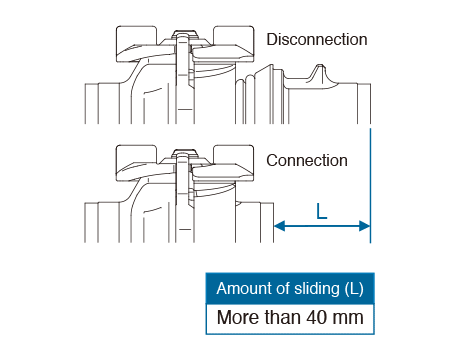

Connection and disconnection of socket and plug is enabled by sliding either the socket or plug to the central axis of pipe. When connecting the couplers to the pipe, ensure that there is at least minimum moving distance (L) in the axial direction.

Precautions to be taken when using CUPLA

Precautions to be taken when using CUPLA![]()

・Any residual fluid remaining in the passage will spill out on disconnection. Drain any residual fluid before disconnection to avoid burns or injury to the skin when dangerous fluid such as chemical agent or high temperature fluid is used.

・There is a dead space in the CUPLA. Be careful that this may lead to the spread of bacteria.

・The CUPLA can be easily disassembled for cleaning. The CUPLA should be evaluated before use to determine the suitability with regard to sanitation and safety. Especially when using O-rings of other brands than Nitto Kohki, be sure to evaluate the O-ring at your end.

・Do not use the CUPLA continuously under any pressure exceeding the rated working pressure.This may cause leakage or damage.

・Use only within range of its rated temperature. May cause damage or deterioration to the sealing and leak if used otherwise. Also, do not use continuously at the lowest or highest working temperature.

・The durability of the CUPLA differs depending on the operating environment and conditions (pressure and temperature etc.). If necessary, conduct performance evaluation test under your actual operating environment and conditions.

・Connection and disconnection of socket and plug is enabled by sliding either the socket or plug to the central axis of pipe. When connecting the couplers to the pipe, ensure that there is at least minimum moving distance in the axial direction.

・The outer diameter and thickness of the pipe to be welded to the CUPLA must conform to JIS G 3447.

・Malfunction caused by welding (directly or otherwise) is not included in the warranty.

・When powder is applied to the CUPLA, static electricity may be generated. Please take countermeasure against this if required.

・When the CUPLA remains connected for long periods of time, it may become difficult to disassemble.

In this case, do not forcefully turn the socket and plug to disconnect as this may damage the seal material and cause leakage.

・The O-ring and Lock plate ASSY are consumable items.

・See the following list as a replacement guide for the Lock plate ASSY.

・When the Lock plate ASSY is deformed, replace it with a new one regardless of connection/disconnection times.

・The durability of the O-ring differs depending on the operating environment and conditions (pressure and temperature etc.).

・Be sure to read the "Instruction Sheet" that comes with the product before use.