Cart0

Your shopping cart is empty!

Product Details

Product Name:HSS End Mills

Manufacturer:NACHI

Availability:out of stock 0 item(s)

Product Code:

More Information :

Description

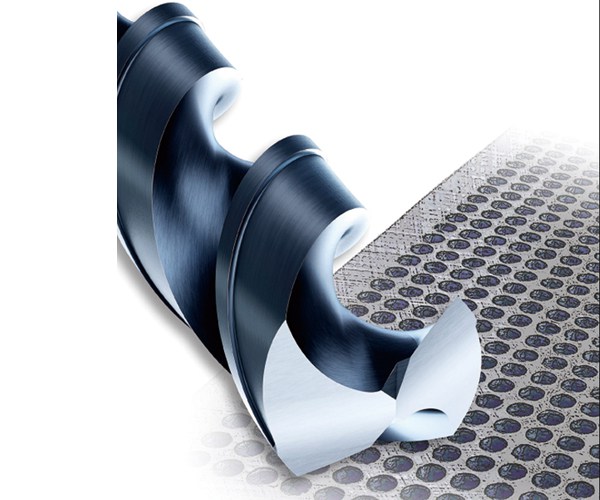

• High-efficiency machining

- Perfect balance of wear resistance, toughness, and chipping resistance, high-efficiency machining, and a long tool life are achieved with the newly developed high-alloy HSS, TiAIN-based AG coating made with a new process, and optimum end mill design

• Stable machining tool life

- Adopts a fine pitch nick to minimize cutting resistance

- Delivers stable performance in heavy-cutting, pre-finish grooving and side milling.

Achieves wear resistance, toughness, and chipping resistance

AG-mill Roughing |

Competitor powder HSS-TiCN |

|

Conditions

|

No re-coating required after re-grinding

|

Comparison of initial and re-grinding performance  |

Conditions

|

Grooving of S50C (180HB)

Comparison of cutting length up to baseline tool life

AG-mill Roughing After cutting 6 m |

Competitor powder HSS TiCN coating |

|

Conditions

|

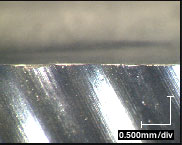

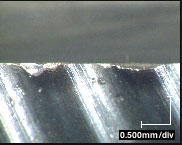

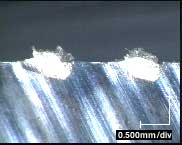

Side milling of SKD 11 (210HB)

Comparison of wear of cutting edge

AG-mill Roughing |

Competitor powder HSS TiCN coating After cutting 5 m |

Wear in side milling

|

Conditions

|