Product Details

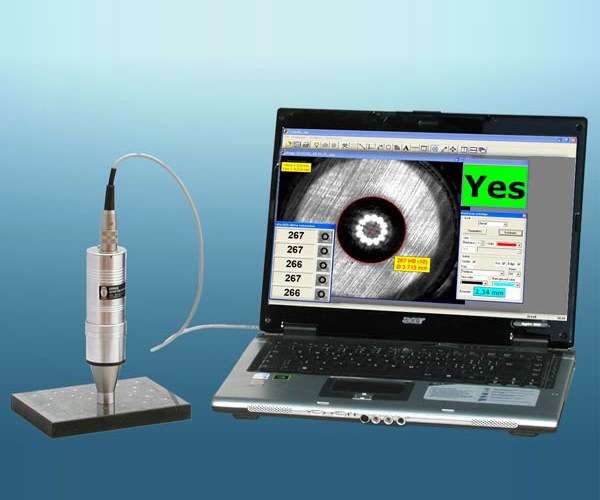

Product Name:Brinell Check Video Measuring Instrument

Description

Brinell Check is a small video instrument (it can be hold in a hand) able to measure automatically the Brinell hardness value or "calibrated shear pin" on indents from 0,5 mm to 2,5 mm or from 1,5 mm to 5 mm of diameter (made in two versions). Equipped with a stainless steel body and a magnetic base, it can stay in an erect and stable position above the indent allowing an image vision perfectly clean and ensuring careful and constant measurements.

Placing the Brinell Check on a flat or curved surface and pressing the acquisition button, the image of the indent, with the relative hardness and diameter values with thousandth of micron, are sent to the PC or to the laptop.

Through the setting of a tolerance value on the measurements to be made, the user will have the possibility to evaluate visually the accuracy of the indent, thanks to a "YES/NO" response which will appear in an unequivocal way on the monitor.

Moreover it's possible to make appearing on the screen, in an automatic succession, the values of the last five hardness measurements made.

With Brinell Check is possible to work up to 10 meters far from the work position thanks to the availability of Video Power cables and thanks to the software possibility of enlarging on the monitor, the label of values and the centre of pointing.

The images with their content can be saved automatically in a predefined folder, while in a compatible file with Excel are archived all the information relative to: identification of the user (number or name), date/hour, parameters on the hardness test, measured hardness values and path of the saved image.

The adopted technical-video solutions, the characteristics of the software and the excellent "quality-price" relation, make the Brinell Check one of the most performing tool still present in the sector.

WORKING OF BRINELL CHECK SOFTWARE

In the software supplied with the Brinell Check, it is possible to select the type of Brinell hardness to measure (Brinell or "calibrated shear pin"), the visualization of the label with the measurement made (dimensions, colours, font) and other selectable parameters, like:

Settings on the hardness test made:

BRINELL:1 - Diameter of the sphere (you can choose the value of the diameter of the sphere used for the

hardness test between 1, 2, 2.5, 5 and 10 mm)

2 - Load applied (from 1 to 3000 kg, or from 9,81 to 29430 Newton)

3 - Duration of the test CALIBRATED SHEAR PIN:

- Type of load applied (dynamic or static)

- Type of indenter (normal or in carbide)

- Type of material on which the test has been made (steel or cast iron)

Settings of the possible measurements:

4 - To show the label of the measurement with information about the diameter of the sphere/load

applied/duration of the test

5 - To modify the measurement tolerance

6 - To show on the screen the latest 5 measurements

7 - Calibration of the brightness

It is also possible to select and automate some operations of external input, just pressing a single button, such as:

8 - To duplicate the image on the screen

9 - To measure the indent

10 - To save the image selected in the format, with the options and with the name wished

11 - To export in an Excel table the measurements made

12 - To close the image after the measurement after a fixed waiting time

13 - To warn if the space on the disk is not enough to save the image

MIN-MAX method to measure indents on surfaces with imperfections

Since often in the empiric working, for matters of time (but also of costs), materials not enough smooth and not standardized are used, some problems in the measurements.

For this reason we suggest this method (probably it will be the most used..!)

This method allows to have very reliable measurements, but you must wait for a few seconds more to visualize the indent with relate diameter and Hardness Brinell value.

Settings saving in profiles

If measurements are made on different types of material, you need to save all parameters to use them in the future on the same type of material.

The Brinell profiles are designed specifically for this purpose, because when you find the ideal parameters to make your measurements, you can save and recall them whenever you need.

|

|

dimensions: Ø43x270mm

weight: 650g

power supply: 12V

absorption: 300mA

CCD: B&W 1/3"

vision and measuring in live

input video/PC: USB2.0

MINIMUM REQUISITES OF THE PC/LAPTOP

processor: Intel Pentium 4 or compatible

operative system (32/64-bit versions): Windows XP, Vista, 7, 8, 8.1, 10

graphical extensions: DirectX version 9.0 (or better)

RAM memory: 1Gb

memory on disk: 10Mb

video card: 256Mb (or better)

3 USB2.0 input ports

BRINELL CHECK

WITH POWER CARRYING CASE BR

(code BC 10386 - for indents from 1.5 to 5 mm)

(code BC 10443 - for indents from 0.5 to 2.5 mm)

The PC / Laptop is not included.

The working autonomy of the Brinell Check is guaranteed for eight consecutive hours, while the reload last about two hours directly connecting to a socket with a voltage of 100/240V 50/60Hz.

Thanks to the potentialities of the software in outfit, linking with a special cable to the Power Carrying Case, it is also possible to use other video systems already existing in the agency to make various types of measurements, comparisons, fillings, etc.

THE BRINELL CHECK SYSTEM (CODE BC 10386 / BC 10443) IS SUPPLIED COMPLETE OF:

Video-optical head for Brinell Check

Video-optical head for Brinell Check

(indents from 1.5 to 5 mm)

code SPT OVT 000448

or

Video-optical head for Brinell Check

(indents from 0.5 to 2.5 mm)

code SPT OVT 000668

Video power cable B for Brinell (2,3 m)

Video power cable B for Brinell (2,3 m)

code SPT OVT 000453

![]()

Set USB2.0 interface for PC or Laptop with Brinell and

Set USB2.0 interface for PC or Laptop with Brinell and

"calibrated shear pin" indents measuring software

(inside the case)

code USB 10359

USB cable

USB cable

(inside the case)

code SPT OVT 000454

Supply set (battery and battery-charger)

Supply set (battery and battery-charger)

(inside the case)

code SPT OVT 000475

Power Carrying Case BR: Small and strong case in printed aluminium full of all the accessories and electric parts already wired (battery, battery-charger, etc...) ready to be connected to the USB ports (USB2.0) of a PC or a portable one through its USB cables.

Power Carrying Case BR: Small and strong case in printed aluminium full of all the accessories and electric parts already wired (battery, battery-charger, etc...) ready to be connected to the USB ports (USB2.0) of a PC or a portable one through its USB cables.

(dimensions: 380x266x150mm; weight 5,5Kg;

Input voltage for the reload: 100-240V; 50/60Hz)

code VAL AMA 0000511

BRINELL CHECK

WITH CARRYING CASE STATION BR

(code BC 10387 - for indents from 1.5 to 5 mm)

(code BC 10444 - for indents from 0.5 to 2.5 mm)

The PC / Laptop is not included.

A practical and robust carrying case "in printed aluminium" able to contain and feed autonomously the complete set which composes the Brinell Check is now available.

Very compact, the Carrying Case Station BR is arranged to be operating in less than two minutes.

The space inside the carrying case has been optimized to contain, besides the set Brinell Check (battery, battery-charger, and so on) also a laptop and various documentations.

The big autonomy of the battery guarantees the Brinell Check about five hours of consecutive work, while the reload can be made also during the use.

A series of LEDs alert the operator of the remaining autonomy while the battery recharges in 8 hours.

FEATURES

External dimensions: 400 x 500 x 150 mm

Weight (excluded laptop): 6 kg

Maximum laptop dimensions: until 17"

Input for the reload: 100-240V; 50/60Hz

BRINELL CHECK POWER KIT

(version lite - code BC 10385 - for indents from 1.5 to 5 mm)

(version lite - code BC 10388 - for indents from 0.5 to 2.5 mm)

Brinell Check Power Kit (code BC 10385 / BC 10388)

THE BRINELL CHECK POWER KIT SYSTEM (CODE BC 10385 / BC 10388) IS SUPPLIED WITH:

|

Video-optical head for Brinell Check

(indents from 1.5 to 5 mm) code SPT OVT 000448 or Video-optical head for Brinell Check (indents from 0.5 to 2.5 mm) code SPT OVT 000668 |

|

Video power cable B for Brinell (2,3 m)

code SPT OVT 000453 |

|

USB assembly box for Brinell Check

code SPT OVT 000639 |

|

Measuring software for Brinell

and "calibrated shear pin" indents code FVK 10143 |

|

2 USB cables

code SPT OVT 000454 |

OPTIONAL

|

Video power cable B for Brinell (5 m)

code SPT OVT 000577 |

|

Video power cable B for Brinell (7,5 m)

code SPT OVT 000578 |

|

|

Video power cable B for Brinell (10 m)

code SPT OVT 000579 |

|

|

BR case: case for Brinell Check made in printed aluminium.

Overall dimensions: ext. 380x265x150; int. 350x250x140 code VAL AMA 000212 |

OPTICAL DEVICES FOR THE BRINELL MEASURING

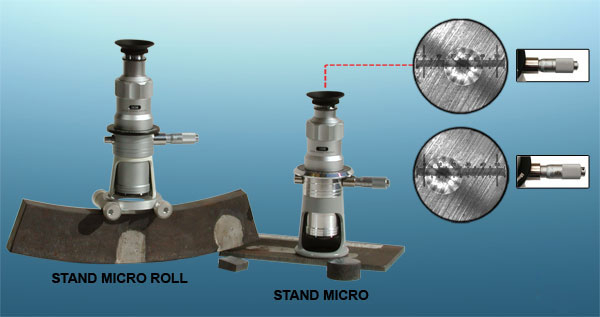

STAND MICRO

The Stand Micro is a pocket microscope 20X/40X very strong, completely in aluminium, practical and manageable.

It can be used as tool of universal measure for the control of surfaces, to measure the diameter of small holes, meshes of textiles, etc., but thanks to its particular technical characteristics it has been immediately appreciated as ideal optical instruments of Brinell indentations.

Its led annular lighting (6000°K) incorporated high luminous intensity allows easy measurements of cracks in the materials on plain and curved surfaces (this last if provided of special base).

The precise focusing by means of knurled metal ring coaxial with optical axe allows the control and measuring in movements on “Z” axe up to 7 mm through a nonius with decimal divisions.

The ocular is provided of a measuring reticle of 6mm with divisions of 0,05mm and it is possible to regulate it in the focusing suiting it for your sight.

The alignment of the division notches with the object to be measured comes rotating the block of the ocular avoiding in this way the moving of the tool or the object under examination.

The great practicality in the use of this device is due in particular way to the possibility of transversal micrometrical movement of the optical head on the object to be measured through a screw cursor.

The maximum excursion of the cursor is 8mm and is controllable on its nonius with centesimal divisions; with this system is possible an express and precise alignment of a scale division of the ocular with a point of the object to measure.

|

2012 Stand Micro |

|

Magnification: |

-

|

20X

|

40X

|

| Field of view: |

-

|

7.2 mm

|

4.3 mm

|

||

| Min. scale division: |

-

|

No.16: 0.05mm

No.17: 0.0025” (on request) |

No.18: 0.02mm

No.19: 0.0010" (on request) |

||

| Nonius division: | - |

0.01 mm

|

|||

| Z axis nonius division: | - |

0.1 mm

|

|||

| Measuring range: |

-

|

8.0 mm

|

|||

| Working Distance: |

-

|

22 mm

|

28 mm

|

||

| Case: |

-

|

245x160x100mm

|

|||

| Total weight with case: |

-

|

1400 g

|

|||

|

|||||

STAND MICRO ROLL

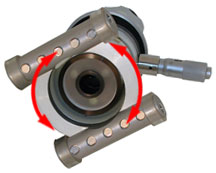

In order to allow a comfortable and immediate frame of the surface to examine or to measure (cylinders the much long or of large dimensions) the base is revolving.

On request at the order STAND MICRO ROLL can be supplied of magnetic base.

|

2012-A

2012-AM Stand Micro Roll |

|

Magnification: |

-

|

20X

|

40X

|

| Field of view: |

-

|

7.2 mm

|

4.3 mm

|

||

| Min. scale division: |

-

|

No.16: 0.05mm

No.17: 0.0025” (on request) |

No.18: 0.02mm

No.19: 0.0010" (on request) |

||

| Nonius division: | - |

0.01 mm

|

|||

| Z axis nonius division: | - |

0.1 mm

|

|||

| Measuring range: |

-

|

8.0 mm

|

|||

| Working Distance: |

-

|

20 mm

|

35.5 mm

|

||

| Case: |

-

|

245x160x100mm

|

|||

| Total weight with case: |

-

|

1400 g

|

|||

|

|||||

- Models: BC-10386, BC-10443, BC-103872, BC-104442, BC-10385, BC-10388, BHT-10441 & BHT-10442