Product Details

Product Name:Robot function packages & commissioning

Description

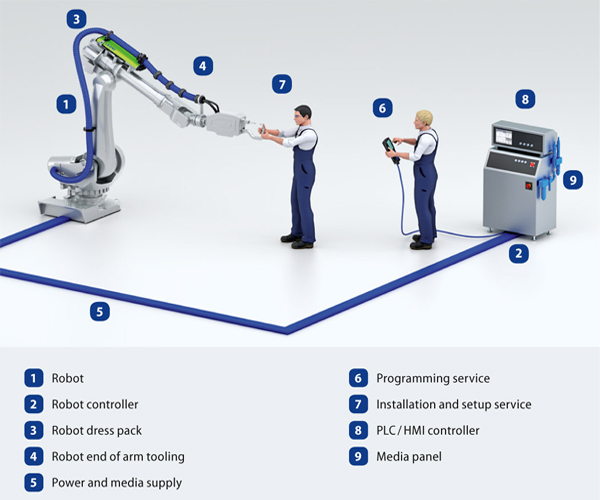

Integration-Ready-Robots

We provide “Integration-Ready-Robots” including e. g. the robot dress, optimized dress packages, installed tools, installed process controllers, dense packs, electrical junction boxes etc. Amongst others we configure, set-up and test welding guns, software and Tool Center Point and also take care of the logistics.

Your advantage: one-stop

The path from developing processes to starting production is a long one, and is characterized by many points of interface between production and business systems. Once we have done our work and the function package is ready, all that is left for you to do is plug in and produce. This is how we operate: We plan for you and select only the best components. All the systems we design are assembled, set up and configured to your requirements. We take care of all coordination of components involved in the process, including the robot, and ensure that the corresponding programming, robot and tool calibration is in place. The brand of the robot – that you provide us with – does not matter.

When all tests have been faultlessly completed, the system is packed securely for transport and delivered to the set-up location. It is your choice where we assemble the system, either at our LEONI facilities, at your line builder or on-site. Thereafter, we will take care along with you of the final coordination and integration into the production process. We will familiarize your staff thoroughly with the system and, in the shortest possible amount of time, your robot will be welding its first spots, carrying out the handling and assembly tasks or commence calibrating or gluing. We provide first-class support after production has successfully started as well: We train our customers’ employees, maintain the equipment and replace wear parts in a timely manner. This minimizes production downtime and saves a lot of expense.

Should a problem arise nevertheless, LEONI customers have a prompt repair service at their disposal.

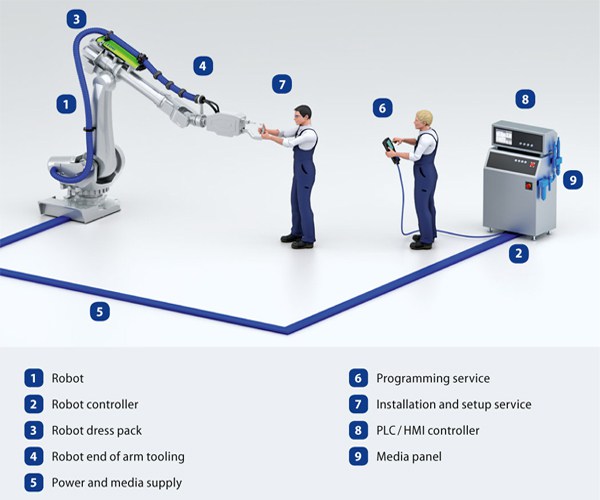

Overview scope of supply

Find out more about our scope of supply regarding:

Products

- Cables and cable assemblies

- Hoses

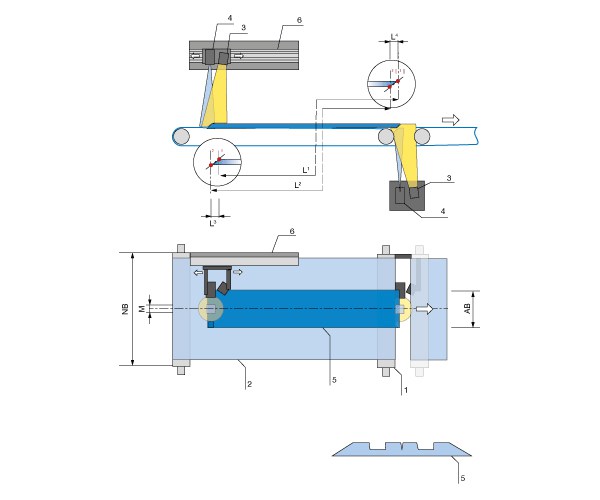

- Robot dress packages axis 1 to 6

- Interface plate on axis

- Air & water preparation unit, dense pack

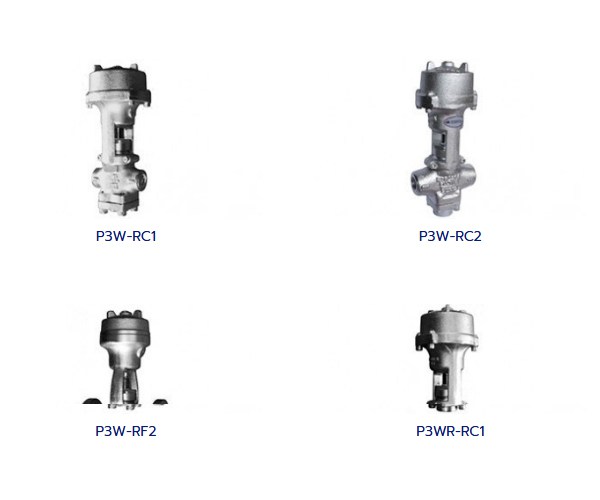

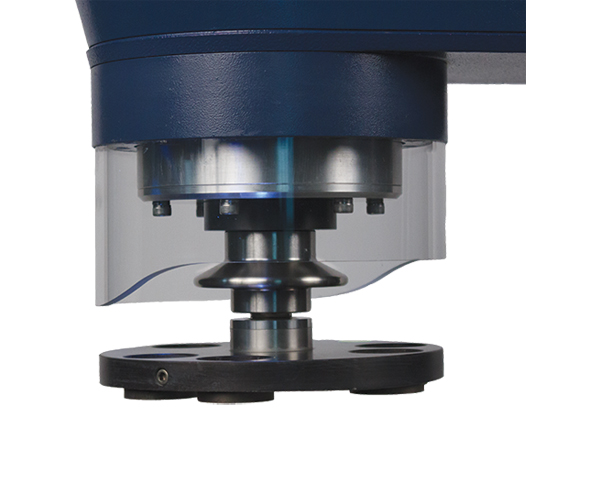

- TCP calibration unit

- Safety & internal controller auxilary circuit wiring

- All robot brands and arm types*

- Robot controller*

- Process controller*

- Process specific operation panels*

- End of arm tooling*

* Products typically provided by customer

Engineering

- Electrical and mechanical expertise

- Product design (i. e. cable, connector interface, dress pack support systems)

- Software development

- Specifications development

- Custom system documentation

- Revision drawing updates

Services

- Robot operating software load and upgrades

- Dress pack optimization and system verification

- Software development

- Robot system set-up, configuration, test and validation

- End of arm tooling set-up, debug and verification

- Weldgun calibration

- High accuracy robot calibration

- Download off-line programs

- Perform pay load verification

- In-field programming

- TCP set-up and verification

- System start-up and program launch support

- Run off

- Logistic services

- Project management